Rossi utilizes a perfect type of papers using fibers that are soft and readily accepts the impression as well as the ink. The nature of the process requires a paper that is high quality… both heavy weight and pliable that will not tear or thin out when pressed. The printing principle is the same, but they are a different size. It was, and remains, the epitome of automated flat platform, or platen, press design. For Rossi’s decorative sheets, big antique letterpresses are used such as the Italian made Nebiolo and the original Heidelberg, created in pre-war Germany. The entire Rossi Letterpress collection is made with traditional letterpress printing machines. Very few paper makers produce letterpress decorative and wrapping papers, as there are very few machines left in the world. Letterpress printing offers that distinction. In a world of mass production, creating something that people hold onto is more valuable than ever. And it holds color elegantly, as if the pressed areas are reservoirs of ink. Letterpress transforms paper into art– it changes it from flat to sculptural.

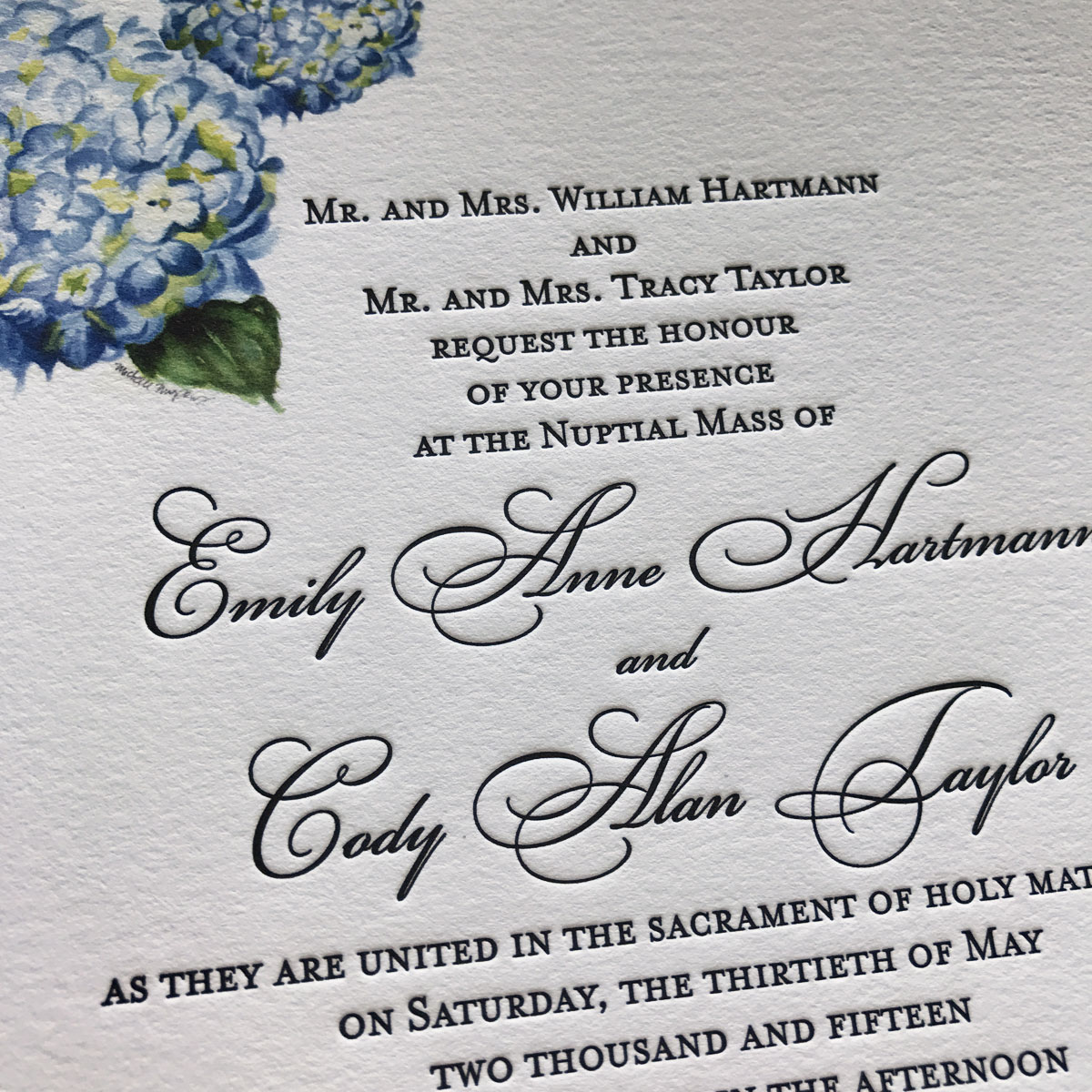

At the same time, presses were being discarded by commercial print shops, and became affordable and available to artisans throughout the world. The beauty and texture became appealing to brides who began wanting letterpress invitations instead of engraved or offset-printed invitations. Renewed interest in letterpress was fueled by Martha Stewart Weddings magazine, which began using pictures of letterpress invitations in the 1990s. But it is so highly valued in today’s world for the unique tactile impression it leaves behind you are drawn to run your fingers across the sheet and feel it… a printing method that cannot be replicated by any other printing process. It is still both time consuming and labor-intensive. Not much is different since the 1400’s, even Johannes Gutenberg (the father of the printing press) would recognize the techniques. Plates are still locked into chases, hand-mixed ink is applied, and then pressed on to the paper and sheets which are fed on and off, one at a time, with each print having its own unique variations of ink coverage and depth of impression. The type is patiently hand-set, locked into a metal frame or chase. Modern day printers today still use moveable type made from metal or wood. The original letterpress printing skills developed centuries ago, used raised metal type cast in individual letters. Surprisingly very little has changed since the first days of letterpress. If you're a lovely shop owner or buyer please do get in touch with us about working on a wholesale basis.Letterpress stationery has been experiencing a renaissance of sorts, after nearly vanishing over the past centuries. We're proud to supply some of the most beautiful gift shops and boutiques around the world with our stationery.

Our online shop brings together our signature letterpress greetings cards, our collection of stationery designed by us and produced in the UK, and also a collection of the very best stationery brands from around the world! It’s mechanical, oily and inky and we love it! We print all of our greetings cards in our range in-house on our 1960’s Heidelberg printing press. We’re all about letterpress, a centuries old technique in which ink is applied to a raised design and then pressed into the paper, resulting in a beautifully textured embossed impression on the page. is a luxury stationery brand based in Northern Ireland, designing and producing a range of greetings cards and stationery in-house. We combine playful modern design and illustration with the beautiful tactility of traditional letterpress printing. Hi 👋 I’m Emma, owner and designer here at Hunter Paper Co.

0 kommentar(er)

0 kommentar(er)